principle of vertical roller mill

LUM Ultrafine Vertical Roller Mill Jaw Crusher. LUM ultrafine vertical roller mill working principle. The main motor drives the disc to rotate by the reducer, at the same time the .

WhatsApp)

WhatsApp)

LUM Ultrafine Vertical Roller Mill Jaw Crusher. LUM ultrafine vertical roller mill working principle. The main motor drives the disc to rotate by the reducer, at the same time the .

working principle of roller mills – Gold Ore Crusher. Roller mill – Wikipedia. Roller mills use cylindrical rollers to grind all sorts of materials rather than crushing them or .

Loesche vertical roller mills for the comminution of ores and minerals. PRINCIPLE OF THE LOESCHE MILL LOESCHE has been manufacturing vertical roller mills for cement raw materials, clinker and slag, indus trial minerais, and...

Working Principle Of Roller Mill Vertical Roller Mill Structure Grinding disc: including guide ring, wind ring, retaining ring, lining plate, disk, scraper plate and lifting device, etc.. Grinding roll: roll sleeve is easy to wear parts, requiring sufficient toughness and good wear resistance.

Although there are many roller compactor machines available in the market with various parts and components, the working principle still remains the same. In this article, I will explain how a pharmaceutical roller compactor works. I will focus on how you can use this knowledge to achieve maximum productivity in any material processing environment.

HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng. The equipment referenced the operating principle of pendulum mill and improved the swinging method. Without changing other parameter, the centrifugal grinding pressure increased about 35%.

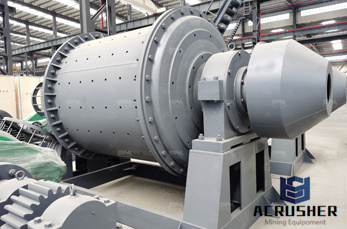

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Tag: triple roller mill principle. Manufacturing Technology. rolling operation or roll mill its types and application. techminyNovember 25, 2016. 0. What is Rolling mills or Rolling Operation: Rolls (or) Rolling mills is a cylindrical shape of roll used in rolling process. The housing and...

Roller mill is a form of compression mill that uses a single, double or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials.

The working principle of rubber two roller mill Two Roll Mills. Sep 28, 2013 ... Rubber two roller mill principle of work: rubber two roller mill why can the high elasticity of raw rubber into plastic state plasticate rubber? Read More. Vertical roller mill Wikipedia, the free encyclopedia.

Principle. Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type, ball type, etc., and roller surface is also flat, curved, convex round noodles. Applied to the grinding roller to roller grinding along the track bed in close contact with the material strength of a spring pressure, hydraulic, etc.

Working Principle of Roller Mill LHG: Roller mill LHG has the similar working principle to superfine impact mill and jet mill: 1. Feeding and grinding: After the materials are fed into milling chamber, they will be ground into superfine powders by grinding roller. 2. Classification: relatively coarse and fine powders will be separated from each ...

Apr 21, 2015· Gebr. Pfeiffer MVR Roller Mills In the cement industry, MVR roller mills are used for grinding cement raw material, cement clinker, granulated blastfurnace slag, and pozzolana. Such bulk ...

Roller mill Wikipedia. Fourroller mills Fourroller mills have two sets of rollers. When using a fourroller mill to mill grain, the grain first goes through rollers with a rather wide gap, which separates the seed from the husk without much damage to the husk, but leaves large grits.

Feb 11, 2017· Vertical Roller Mill Training by PAI This video was made by PAI which introduce the working principle of Vertical Roller mills.

Edge runner mill. Edge runner mill also known as Chilean mill or Roller stone mill consists of one or two heavy steel or granite rollers mounted on a horizontal shaft and turned round a central vertical shaft on a bed of steel or granite.

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it.

Raymond Mill. Raymond mill, also known as Raymond, Raymond machine, instead of a ball mill processing ore powder milling mill, Raymond mill grinding roller centrifugal force in tightly pressed on grinding ring Therefore when roller, grinding ring wear to a certain thickness does not affect the yield and the fineness of the finished product.

Roller Mill For SaleSuper Crusher For Sale Roller Mill Working Principle. Roller Mill package of equipment by the host, reducer, analysis machine, plumbing fixtures, blowers, dust, jaw crusher, bucket ...

Principles Of Roller Mill. roller mill principle – Grinding Mill China. Vertical roller mill feature and working principle. Vertical Roller Mill is my company based on the extensive use of advanced technology at home and abroad, and combine many years of experience in a variety of mill. Get Price And Support Online

principles of operation, there are four main advantages that direct people to use a roller mill rather than a hammer mill, ball mill, cone mills or some other. Get Price Particle Size and Standard Deviation .

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it.

Working and Principle of Colloidal Mill ... The basic principle used in the colloidal mill is known as rotorstator which is placed in a cylindrical vessel. The rotor and stator are placed close enough to create a narrow passage where the material to be reduced in size are passed through. That is why the process is known as shearing, because of ...

Definition, objectives of size reduction and size separation, factors affecting size reduction, laws governing energy and power requirements of mills including ball mill, hammer mill, fluid energy mill etc., sieve analysis, standards of sieves, size separation equipment shaking and vibrating screens, gyratory screens, cyclone separator, air separator, bag filters, cottrell precipitator ...

WhatsApp)

WhatsApp)