Statewise Plant List

Zuari Cement Ltd Chennai Grinding Unit 24. TELANGANA 1. Sri lalitha Cement Industries Ltd 2. Anjani Portland Cement Ltd 3. Bharti Cement Corpn. Pvt. Ltd 4. Cement Corporation of India Ltd .

WhatsApp)

WhatsApp)

Zuari Cement Ltd Chennai Grinding Unit 24. TELANGANA 1. Sri lalitha Cement Industries Ltd 2. Anjani Portland Cement Ltd 3. Bharti Cement Corpn. Pvt. Ltd 4. Cement Corporation of India Ltd .

The N95 Shortage: OSHA Issues Guidance For Respiratory Protection Due to the COVID19 pandemic, OSHA has issued interim enforcement guidance to help combat supply shortages of disposable N95 .

Unit: Concrete grinding LMFFL2107A: Select, operate and maintain grinding equipment Section 2: Practice of grinding. ... Make sure the extension lead is heavy enough to take the current required. ... you still need to be careful when you''re dusting down the machine and cleaning up the work area .

Area of plant Approx. 32 acres 7. Toposheet No. 58 E/9 8. Latitude ... Water Requirement 500 M3/day and the total water required for operation the Cement Grinding Unit will be ... Since, JSW Cement Limited is proposing to set a mtpa cement grinding unit .

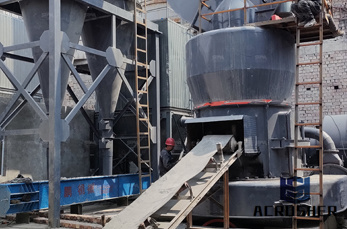

In general, a complete cement plant is mainly composed of the following units: raw meal preparation unit, clinker calcination unit, cement grinding unit, and cement packing unit. You can choose the production equipment required by the cement plant according to the actual situation.

Units are required to be at least 5 in. (127 mm) thick, with a minimum gross area compressive strength of 2,500 psi (17 MPa) (average of 3 units) or 2,000 psi (13 MPa) for an individual unit, and a maximum water absorption of 10 pcf (16 kg/m³) (average of 3 units).

Jaypee Sikandarabad Cement Grinding Unit (JSCGU) 19 20 Industrial Area, Distt. Bulandshr, Sikandarabad () 203205 Tel.: (05735) 222573, 224242, 221868, 221069

JK Cement, India''s premier cement company laid the foundation of a grinding unit in Balasinor, Gujarat. Once fully operational, the unit will have a total output capacity of MT annually.

The cost of concrete grinding is affected by five key factors; Size of the floor; As you''d expect, the larger the floor, the less you''ll pay. This is due to the economies of scale. When determining the cost per .

In the kiln area, 100 short/medium stops (30 minutes to eight hours) per year can cost up to 5kWh/t clinker. The avoidance of inleaking air, correct alignment of motors, stopping compressed air leaks, etc are all part of the value of good maintenance. In the key area of grinding .

Vertical mills are the standard grinding equipment in both types of installations. While many smaller mills with 3,000 kilowatts or less installed power were sold in 2016, the largestever VRM was sold with 11,600 kilowatts installed power. Capacity requirements for new cement plants and grinding units .

MasterCem Grinding aids that improve cement performance by increasing mill throughput and lowering the clinker factor How do MasterCem cement additives improve cement performance? BASF''s MasterCem product family encompasses an extensive range of grinding .

RattanIndia is commissioning cement grinding unit at additional Sinnar Industrial Area, MIDC, Nasik (Marashtra). It has an over all capacity of million tonnes per annum out of which capacity of million tonnes per annum has already been commissioned . The flyash for manufacturing of cement .

RattanIndia is commissioning cement grinding unit at additional Sinnar Industrial Area, MIDC, Nasik (Marashtra). It has an over all capacity of million tonnes per annum out of which capacity of million tonnes per annum has already been commissioned . The flyash for manufacturing of cement will be sourced from Nasik

Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous, dry (<% moisture) and super fine (1020% residue on 90micron sieve) raw meal powder for clinkerization process in kiln (Dry Process). Grinding operation is monitored for following ...

CemMate Technology Raise Cement Plant Profit The application of CemMate additives can realize the following economic benefits. > Lower the clinker content by ~5%. > Increase the utilized industrial waste residue content by ~5%. > Reduce power consumption of cement grinding by ~10%. For cement plant with annual output of 1 million tons of cement.

The Company was established in 1994, the first grinding unit in Goa to cater to the requirements of the cement market in Goa with 200 TPD single grinding and packing unit. The Company was started to manufacture Portland Slag cement by utilizing the by product of .

acres of the area has been leased out to LIL by the TISCO for operating the grinding unit. Green belt in an area of more than 45 Acres has been developed inside the plant boundary as per statutory norms. No additional land is required for change. There is no wild life sanctuary, national park, ecosensitive area

The emergence of Portland cement in the 1840s made grinding considerably more difficult, because the clinker produced by the kiln is often as hard as the millstone material. Because of this, cement continued to be ground very coarsely (typically 20% over 100 μm particle diameter) until better grinding technology became available.

>6 grinding accessories required per loading : Ideal for: >Production grinding and floor cleaning on large or small surface areas such as airports, warehouses, parking decks, manufacturing plants, malls and sports arenas >Light grinding or cleaning of concrete .

Apply for Cement grinding unit jobs. Explore all + current Jobs in India and abroad. Fulltime, temporary, and parttime jobs. Competitive salary. Job email alerts. Fast Free. Top employers. Cement grinding unit jobs is easy to find. Start your new career right now!

If you need to cut into concrete, check out our concrete saws available to rent. Not sure what you need? Call United Rentals today . Can you cut or grind concrete with an angle grinder? Angle grinders were not designed to grind concrete.

Mar 11, 2020· CCI has proposed to install a clinker grinding unit near the project area, which, besides fulfilling the cement requirements of the project, will also generate employment opportunities in the area ...

Cement manufacturing is the source of 5% of global CO2 emissions. The cement industry is a natural producer of CO2: 60% of emissions are due to the transformation of raw materials at high temperatures (the "decarbonation" of limestone), 40% result from the combustion required to heat the cement .

WhatsApp)

WhatsApp)