Interlock Chocolate/MultiUse Mill — RAW DESIGN

Back to Top. email: bob phone:

WhatsApp)

WhatsApp)

Back to Top. email: bob phone:

An interlock is a feature that makes the state of two mechanisms or functions mutually dependent. It may be used to prevent undesired states in a finitestate machine, and may consist of any electrical, electronic, or mechanical devices or most applications, an interlock is used to help prevent a machine from harming its operator or damaging itself by preventing one element from ...

cabinet and check also the status of fan motor and cooling system. If the problem persists, replace the cooling fan. Check the resistance of the regenerative power discharging system, and replace the system if .

USAmade machine safety guards and shields for industrial machine tools. Durable aluminum construction, powder coated "OSHA safety orange."

Okuma OSPP300S/P300L AlarmA list. For cnc machinists who work on cnc machines with Okuma cnc controls. Classification Of Okuma Alarms Alarms related with

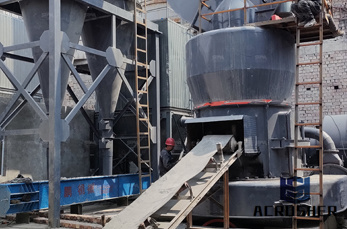

POLYCOM® highpressure grinding roll. The proven energysaving grinding system. One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated ...

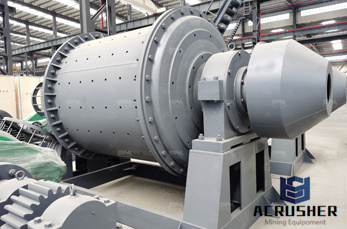

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

block diagram of raw mill coal mill section in flow diagram of raw mill and kiln esp system Gold Ore Crusher, line diagram of ht motors 4800 kw for raw mill More Info; Cement kiln Wikipedia The cement kiln system is designed to accomplish these processes Early history Portland cement clinker was first made (in 1825) in a modified form of .

Zero return alarm troubleshooting, how to repair and find problem or cause. Learn how zero return and encoder determine home position on all your equipment and CNC machine tools

2006 STURTZ F106 INTERLOCK MULLION END MILL ROUTER, S/N 23464. In Ventana Windows ... Inventory Raw Materials. LARGE QTY of Finished Window Inventory, Vinyl Extrusions, WIP, Door Slabs, Hardware, Consumables, Wood, Etc. ... including motor vehicle ownership documents, which are in possession of the Auctioneer, will be provided to the ...

Door interlock circuit and safety interlock module troubleshooting and tips: What you should check in your safety circuit? Make sure all door interlock keys are fully engaged at rest position. Check the interlock modules in the control cabinet. Usually there are LEDs that may help you .

Jul 25, 2016· Wiring a Magnetic Reversing Motor Starter with Interlocks ... In this guided application exercise we''ll wire up and test a three wire magnetic motor starter we introduced in a previous lecture ...

Oct 19, 2006· What it is the optimun speed for a ball mill ? posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use in a ball mill (the pvc cylinder that i use, left of the shafts). With the motor i will use a 40 mm pulley, because i have a 50 mm driven pulley, in one of my two shafts. In the other side of my shafts there are two 40 mm ...

Mar 13, 2007· Interlocks serve as safety devices on industrial equipment and many consumer products. This article explains some applications, describes different types of interlocks, and provides recommendations for resources that can help you determine the requirements for interlocks, along with their advantages and disadvantages.

It''s a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etc. Do your know how does the raw mill work in the cement plant? This paper mainly introduces the raw mill .

Optimizing air flow through vertical roller mill (VRM) ············ 32. Interlock apron conveyor to crusher motor to ensure maximum loading of crusher... Get Price. LoescheMills for cement raw material LOESCHE ... Included are the main parts for the Raw Ball Mill, Preheater, Rotary Kiln, Grate Cooler and Ball mill for Coal ...

handle the extruded chip as a rework raw material if manufactured ''out of specification'' than once the powder has been micronised. Micronising of the chip into the final powder The chips are ground to the required particle size in a grinding mill. The chips are fed onto an enclosed grinding wheel with stainless steel pins, which breaks

The problem with this approach is, while it works, it simply works too fast. Optimum roller speed for small homebrew mills is 150–200 rpm. Drills and most AC motors run at 1,750 rpm ( 60 cycle AC.) The answer is to use pulleys and belts or an expensive gear reduction motor to run your mill more slowly. Motors are ubiquitous.

Interlock motor raw mill. Motor separator 4r1s01m1 raw mill ivmain drive motor for vertical raw mill how to align ball mill pinion to drive motor coal mill main drive motor slagcontacto proveedor with mill a mill is a device that breaks solid materials into smaller pieces by gr.

Sugar mill safety – supplement to the Sugar industry Code of Practice 2005 (PN11197) Page 8 of 52 2. Sugar manufacturing operations A sugar mill is a large factory used to produce raw sugar and other products from sugar cane. Mills are made up of a range of industrial plant such as boilers, storage and ... motor). The billets are shredded by ...

File sharing on the ENGTIPS Forums is outsourced to Below is a link to the file: raw_mill_motor_slip_ Get informed, inspired and entertained at Latest news, games, resources, videos and job postings for postings for engineers.

Wiring diagram for late model mini mill with red and yellow emergency stop switch. FC350BJ/110V LMS 1211: 3156: Wiring diagram for late model harbor freight mini lathe with illuminated rocker power switch and safety interlock circuit. FC250BJ/110V LMS 3149

Piñon Ridge Mill Facility Montrose County, Colorado Visus Consulting Group, Inc. November 3, 2009 Appendix A – Process Control Philosophy The source of this appendix is the Piñon Ridge Project Basic Engineering Report prepared by CH2M HILL Engineers, Inc., dated February 4, 2009 (CH2M HILL 2009).

WhatsApp)

WhatsApp)