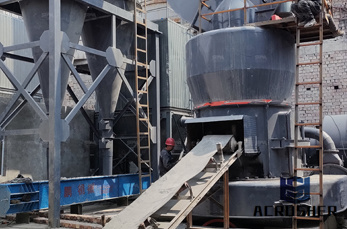

bentonite milling machine

Process of Bentonite Mining Grinding Grinding Mills for Sale. Its Moh''''s hardness is 12, so dry bentonite can be crushed and grinded easily. ... Big size blocks are crushed before feeding to the bentonite milling machine.

WhatsApp)

WhatsApp)

Process of Bentonite Mining Grinding Grinding Mills for Sale. Its Moh''''s hardness is 12, so dry bentonite can be crushed and grinded easily. ... Big size blocks are crushed before feeding to the bentonite milling machine.

Figure 3: milling kinetic of a discontinuous milling process In modeling of a discontinuous milling process, it may be assumed that particle size distribution is not a function of position in the milling good (due to good mixing in the milling process) and is homogeneous over the whole good. The following integral equation describes a ...

Bentonite manufacturing plantntonite mills for saleinding mill is the main bentonite powder manufacturing machinewder grinding is the integral stage in bentonite production process produce fine particle size and prepare for further processingwadays, various types of grindingy grinding ball mill process flow diagram. Learn more

Calcium Carbonate Mill also is named calcium carbonate grinding mill. Calcium Carbonate Mill is suitable for grinding ca . Feldspar Mill Bentonite Mill can be used to grind bentonite into 40 mesh 325 mesh fine powder. The powder output size of bentonite mi . Dolomite Mill Dolomite Mill can be used to grind dolomite into 40 mesh 325 meshget price

bentonite milling process and particle sizing. Nano Sizing Via Wet or Dry Grinding Custom Processing Servic There are many advantages to wet media milling The primary reason to select media milling is that the process can produce uniform particle size distribution in.

The ultimate Bentonite particle is nanosized approximately 1 X 100 x 100 nanometers. High sheer process achieves smaller dispersed particle sizes. It is used as a thickening and suspension agent and as a structural pigment in anhydrous products, suitable for coating applications.

Noncontact mode AFM of the bentonite colloids shows disklike shapes of stacked smectite platelets with a mean heighttodiameter proportion (aspect ratio) of ∼1/10. A broad particle number size distribution is determined by image processing with a mean particle .

Bentonite Mill Production Line Process Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users.

Bentonite A flow diagram for bentonite processing is provided in Figure Mined bentonite first is transported to the processing plant and stockpiled. If the raw clay has a relatively high moisture content (30 to 35 percent), the stockpiled material may be plowed to facilitate air drying to a moisture content of 16 to 18 percent.

DelHur utilizes pugmill processing for the construction of SoilBentonite cap and cover systems, impermeable barriers and landfill cell lining. Process with base soil particle size 3 inch minus Bentonite amending 214% by dry weight of the Base Soil

bentonite milling process and particle sizing SHANGHAI NMN MACHINERY CO., LTD is one hightech enterprise, which involves RD, production, sales and service as well. In the past 20 years, we devote to producing ... Chat Now; bentonite grinding plant process flow Raymond bentonite raymond mill process flow diagram Grinding . ...

bentonite milling process and particle sizing lebhvbe. particle milling gold production australia simplyspicecoza The effects of ball milling time, liquidsolid particle size of325 mesh accounting for 9417%production process and equipment to guarantee a Get firsthand quot.

Industrial manufacturers ( tile, tableware, sanitaryware) commonly process the materials further, slurrying them and screening or ball milling; this is done to guarantee defectfree glazed surfaces. This is what labs use to measure particle size. To measure particle size in a slurry or powder you need sieves.

bentonite pulverizing mill for mining bentonite powder. Ore Crusher,mining air separator! milling and classifying bentonite, Chat Now grinding balls manufacturers for bentonite, Aug 3, 2016, bentonite mining equipment, sulphur bentonite fertilizer Bentonite is an, Bentonite grinding mill,Bentonite Powder Grinding equipment for sale.

The way in which the mill head can be mounted can be adjusted to suit the manufacturing needs, whether that is on a mobile lifter frame or wall mounted within the process equipment design. In addition our High Energy H 20 Comil ® and the Fine Grind F10 can extend the particle size reduction levels. Selecting the right one for you

Finally,purchase a limestone milling production line in our company. Milling process. First, the large limestone minerals are crushed into a certain size particle by a jaw crusher and a counter crusher, and then the crushed limestone particles are lifted into a Raymond mill by a bucket elevator for milling.

Particle size technology for integration in milling and grinding solutions and for automating control. ... Instantly detect a process upset. Milling is often required to reduce particle size to meet a specification that defines product performance. Consistently meeting that specification is a key to marketleading product ensuring continuous ...

Effect of Milling and Particle Size on Functionality and Physicochemical Properties of Cowpea Flour ... gelatinization process were determined using differential scanning ... To assess the affects ...

Fine particle size: Bentonite is colloidal (particles are so small the action of water molecules is enough to keep them in suspension). It is typically 10 times finer than ball clay. It can have a surface area of almost 1000 square meters per gram (50 times that of kaolin, 5000 times that of silica flour).

Organic Modification and Ball Milling of Bentonite and its Retention Properties Article in Applied Mechanics and Materials 197:201205 · September 2012 with 3 Reads How we measure ''reads''

Bentonite raymond mill structure principleSKD Industrial. Generally, when the particle size of bentonite is between 100 and 300 mesh, it is generally processed by a bentonite raymond mill. If the particle size of bentonite is more than 800, the bentonite micropowder is selected for processing, which is also said to be based on the production ...

The role of bentonite particle size distribution on kinetic of cation exchange capacity ... of the activation process is particle size of starting raw materials. ... of alkali solution and ...

Generalized Particle Size Distributions Rationale For Developing Generalized Particle Size Distributions The preparation of sizespecific particulate emission inventories requires size distribution information for each process. Particle size distributions for many processes are contained in appropriate industry sections of this document.

Apr 02, 2018· Barite milling and bentonite crushing machine bentonite and barite milling machines Rock Crusher Mill . bentonite and barite milling machines SKD is a . Bentonite Manufacturing Plant crushershaker. bentonite mills for sale. Grinding mill is the main bentonite powder manufacturing machine.

WhatsApp)

WhatsApp)