How Ball Mills Work (Engineering and Mining) YouTube

Jun 20, 2019· Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill .

WhatsApp)

WhatsApp)

Jun 20, 2019· Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill .

HighEfficiency Milling vs. HighFeed Contour Ramping. Compare cycle time and tooling cost for three approaches to machining a 1" deep x " wide x 6" long pocket in 4140PH (28 Rc): Highefficiency milling – 1/2" solid carbide end mill; Doublepass highfeed ramping – 1" indexable end mill ; Singlepass highfeed ramping – 2" indexable ...

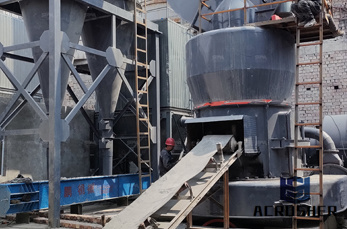

Vertimill® has proven to be a versatile tool that exhibits many advantages over traditional ball milling. It is capable of handling feed sizes up to 6 mm and grinding to products less than 20 microns, and has standard mill sizes ranging from 15HP (11kW) to 4500HP (3352 kW). Support from experts

Mill and float plant modularized in a standard 40ft container. Scope of supply included a loading bin for receipt of material, inclined screwfeeder for constant feed into the closed milling circuit. The flotation circuit consists of the 3 stages of roughers, scavengers and cleaner cells with: froth agitators, air blowers, pumps, reagent ...

ball mill feed screw zimmer Ball Mill Feed Screw Ball Mill Feed Screw in South AfricaSouth Africa Ball Mill Feed Screw Directory provides list of Get Price ball mill for ore extraction process grinding 99 customer review SAG and ball mill for the wet grinding of goldcopper ore in South Australia References Mineral Processing.

Milling Tools. Face Milling ... TAN07 45deg screw clamp type face mills with double sided octagonal or square inserts. ... Super high feed milling endmills with double sided inserts with 4 edges (Economical tool body without air hole)

Used Hosokawa Alpine cryogenic milling 250 CW system consisting of the following: Hosokawa Alpine model A250CW pin mill. Stainless steel construction. 8′ long X 5′ wide X 7′ high. 1200 rpm, 30 HP main drive. Skidmounted blower system. 105 cubic foot feed 316 stainless steel hopper with mirror finish. HP, 42104 rpm feed screw.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Feb 27, 2006· I need a 9/16 hole 2" deep with a ball end mill profile at the bottom and good finish on the sides in 1020 Carbon Steel. Thanks, Scott ... Add to this the fact that you''re applying rotational torque to the knee from the feed screw, and motion from your hand on the feed handle pulling the knee back and forth., 03:54 AM #11. rklopp.

I bit the bullet and converted my mill to use ballscrews like Hoss did. I ordered three lengths of ball screws and three ballnuts from I turned the screws on my minilathe using tungsten carbide bits. once I used a decent cutting angle, it went along nicely. The steel is hardened, but only on the surface.

Stirred Mills have been proven to provide energy savings compared with traditional ball mills. The finer the product required, the more efficient stirred mills will be than a ball mill. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills more energy efficient grinding machines.

Ball end mills are used for drilling shallow holes, slotting a channel where a flat bottom is not required or most commonly used to produce multidimensional contours in molds or dies. The design of ball end mills forms a hemispherical cutting action identical to the diameter of the tool. Because of the shapes required in these products it''s common that multi axis machining

The entire mill feed enters the drum via a chute or spout and an internal spiral carries the feed into the trunnion liner. The drum feeder may be used in lieu of a spout feeder when headroom limits direct spouting. The drum also provides a convenient method of adding grinding balls to a ball mill. The drum is generally lined with Manganese Steel.

A ball mill efficiently operated performs a wide variety of services. In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the SteelHead Ball or Rod Mill will take up to 2″ feed and grind it to the desired fineness. In larger plants where several stages of coarse ...

Aug 11, 2007· Running a ball mill is quite noisy so it is a good idea to operate it in a closed room or basement. Normal materials will take a couple of hours to mill, but harder things like metals can take days or even weeks so be patient. Uses . Grind your own feed (obviously don''t use lead balls for this). Grind sand for glass making.

ball mill feed screw zimmer ... Ball Mill Feed Screw Ball Mill Feed Screw in South AfricaSouth Africa Ball Mill Feed Screw Directory provides list of ... Get Price. ball mill for ore extraction process grinding (99+ customer review) SAG and ball mill for the wet grinding of gold/copper ore in South Australia. References Mineral Processing ...

Aug 02, 2008· All feed screws (ball or otherwise) are going to have some level of backlash. And, over time, it will vary, depending on the level of wear. As steamin10 said, it can lead to the "ting" of little mills or jumps in the table when cutting.

Jun 20, 2019· Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill is charged to approximately 33% ...

Mills Granulators. Perry buys and sells used and second hand mills and granulators / granulation equipment. Used Mills For Sale. Our inventory of mills includes continuous ball mills, colloid mills, comminuting mills (Fitzpatrick), granulating mills and pellet mills.

> BALL CHARGING SYSTEMS. BALL CHARGING SYSTEMS. ... are consumed by all process plants having mills as part of their comminution process. Transmin has a range of systems available to safely store and feed balls from simple kibbles through to complex handling systems. //AUTOMATED BALL CHARGERS //BALL CHARGERS //DRUM KIBBLES //ENGINEERING ...

Batch Type Ball Mill. Batch Type Ball Mill A versatile machine to pulverize even the hardest rocks. This Ball Mill is suitable for wet as well as dry grinding and mixing. Linners, Grinding media may be provided of different hard material like Alloy steel, Ceramic, Granule brick etc...

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Product Category: End Mills Modular Description: Modular Indexable End Mills. Log In. Careers About Us. Open Menu. Products. Indexable Milling. Face Mills. End Mills. Inserts. Slotters. Plunge Mills. ... PowerFeed 13 Plus (3) ProBall (6) RotoMill (2) RoughAir (6) Product Categories. 90° Backdraft Ball Nose Button Corner Round ...

MSC Industrial Supply Co. MSC Industrial Supply, Inc. is a leading North American distributor of metalworking and maintenance, repair and operations (MRO) products and services. With over 75 years of experience, MSC is dedicated to helping customers drive .

WhatsApp)

WhatsApp)