Grinding Mills Columbia Steel Casting Co., Inc. Wear ...

Columbia Steel offers a full line of wear parts for rod mills, ball mills, and semiautogenous grinding (SAG) mills for cement plants. Made in USA.

WhatsApp)

WhatsApp)

Columbia Steel offers a full line of wear parts for rod mills, ball mills, and semiautogenous grinding (SAG) mills for cement plants. Made in USA.

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ 5ROOLQJ ZLWK QLSSLQJ ... Liners protect the outer shell of the mill from wear liners are renewable. 2. Lifters prevent slipping between the medium and slurry charge in the mill and the mill shell. ... This energy is required to cause grinding of the material in the mill. The shape and

The overall wear of the steel in the grinding mills occurs as a peeling of the steel surfaces at a constant radial rate per unit time. This concept although challenged at times was first introduced by Prentice in evaluating the wear of grinding balls, and subsequently demonstrated on large ball mills.

The performance in all media mills is dependent on using the correct media type, size and mill loading. New high performance beads have not only improved mill efficiency but also reduced wear on the beads and equipment. This along with long life easily justify the higher costs associated with these higher performance beads.

Ball mills are common grinding equipment in mineral processing industries. Ball wear results from three mechanisms namely impact, abrasion and corrosion. Of these, the corrosion mechanism is the least investigated, due to its chemicalelectrochemical nature. Therefore, the aims of this research were to investigate the grinding chemistry influence (slurry pH, solid percentage, water chemistry ...

Wear of grinding media. One of the major problems regarding the use of ball mills is to balance the size distribution of grinding media into the mill, which is determined by the speed of consumption and rate of replacement, as the wear of the grinding balls requires

Wide offering. Our comprehensive line of grinding mills, spare and wear parts as well as maintenance and optimization services provide reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operations.

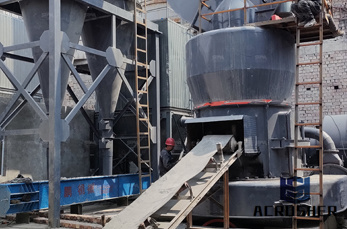

Wear Parts For Grinding Mill Supplier. The Grinding Mill consists of a classifier a grinding roller device a grinding disc device a pressurizing device a speed reducer an electric motor a casing and the like The separator is an efficient energyefficient grading device Grinding rolls are used for material compaction of comminuted parts.

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

Jan 24, 2019· A study was undertaken to investigate the relationship between mill liner wear and grinding energy efficiency and to assess the opportunity to control mill speed to improve energy performance as mill liner wears. The operating work index was found to be an effective tool to identify the decrease of grinding efficiency along the liner service.

highlighted the significance of correct mill liner selection. Liners protect the mill shell from wear and transfer energy to the grinding charge, and a careful balance is required to optimise these conflicting requirements. This review serves to highlight these problems and how they can be tackled in a logical

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Most practical way to by measuring empty height and calculating the % volumetric filling of grinding way to make track of mill main drive kW consumption reduction and add makeup charge according to the extent of fall in power consumption.

The IsaMill is a stirredmedium grinding mill, in which the grinding medium and the ore being ground are stirred rather than being subjected to the tumbling action of older highthroughput mills (such as ball mills and rod mills). Stirred mills often consist of stirrers mounted on a rotating shaft located along the central axis of the mill.

PDF | The combination of a grinding circuit simulator with a model of ball wear in a grinding mill leads to a method to calculate, with a preselected accuracy, the makeup ball charge that ...

Diameter – depending on the material, ranging from mm to 2 mm for small media mills, up to 1/8" to 1" for traditional Attritors and up to ½" to 2" for ball mills Composition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding .

With customer needs and operational risk at the core of design, ''s grinding mills, engineered mill liners, and robust trommels ensure the highest availability. The extensive product support and optimization services help in maximizing the efficiency of your grinding mill, grinding circuit or entire grinding process.

There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift. This type will be used in mills that are designed for primary grinding and as a result require the impact of the higher cascade. Ball mills working as the secondary portion of a grinding circuit will utilize the ...

1. Introduction. The kinetics of grinding media wear is estimated based on theories put forward shortly before the second half of the Twentieth Century, as is evidenced in the work of Sepúlveda, which uses the theory of linear wear to calculate specific rate constant research approaches were found such as that of Albertin and Sinatora, in which ball wear showing linear behaviour ...

Wear In Grinding Mill. Zenith professional rock crusherstone crusher crusher requirement for roadway required safety signs in rock crusher mobile track crusher requirement malaysia cone crusher requirement rock crusher manufacturer from pune requirement for crusher rwanda rock quarry crusher productions requirements requirement of stone crusher work stone crusher plant setup requirement in .

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges ...

SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range. VibroEnergy grinding action achieves higher output per input horsepower; precise control of size and distribution. Product contamination from media and lining wear is virtually eliminated.

Grinding mill process design. Choosing an appropriate grinding circuit configuration depends on your ore characteristics and mine plan. Outotec has extensive knowledge of comminution technologies and processes to ensure we provide the optimal solution for your needs.

The grinding medium should provide maximum performance, minimum wear rate and highest grinding transfer to cost ratio (Jankovic, Wills, Dikmen, 2016). It is important to predict the rate of mill ...

This relates a lifter bar, method for making a lifter bar, a method for assembling a lifter bar and a grinding mill for ore grinding. The lifter bar comprises a lifter bar body having an outer surface conforming the outer surface of the lifter bar, and a fixing element for connecting the lifter bar to the shell of the grinding mill. The lifter bar body further comprises a first portion and a ...

WhatsApp)

WhatsApp)