Energy Information Administration (EIA) Nuclear ...

Nuclear power plants Daily nuclear status/outages (with annual capacity) Daily status of nuclear plants with summary and plantspecific data on percentage output, outage amount, and capacity

WhatsApp)

WhatsApp)

Nuclear power plants Daily nuclear status/outages (with annual capacity) Daily status of nuclear plants with summary and plantspecific data on percentage output, outage amount, and capacity

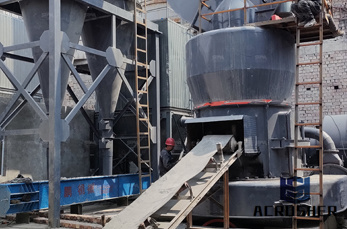

Mar 29, 2017· The basic function of a pulveriser in a Thermal Power plant is to break down and crush the coal lumps into fine particle form before it is taken to the boiler for burning. Pulverisation of coal basically breaks the big coal lumps and increases the...

Thermalbased power plants can produce electricity from coal or other fuel sources. The coalfired process requires three different steps to turn energy released from burning coal to generating electricity for consumption. Coal fired power plants, while producing power, require a lot of water and produce a lot of pollutants like ash and CO2.

Bowl mills are one type of grinding mill used in a coalfired thermal power plant. Raw coal fed into the mills gets converted into pulverised coal and carried to the burners by primary air. Secondary air and sometimes tertiary air is admitted also...

Power plant takes 5 stone and 5 wood in addition to the power requirements and gold cost. Mill is way cheaper. Only time I make power plants is when I need lots of power really fast, or have no room to build mills.

Sugar mills with modern technologies would have a significant amount of excess power and most of these plants would breakeven if they sold excess power at around cents per kilowatt hour.

Coal Mills in thermal power plant, Mill (Grinding. Coal Mills in thermal power plant Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. for thermal powerplant familiarization. TYPES OF MILL Tube or ball mills.

Dec 19, 2017· They are Billions Power Plants Guide to help you learn all about setting up your Power Structures and using them to set up Mills, Advanced Mills, and more.

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

(Chapter 10 was written by Harry Perry under the general supervision of the committee, which reviewed the work at several stages and suggested modifications that have been incorporated. While every committee member has not necessarily read and agreed to every detailed statement contained within, the ...

Wind power first appeared in Europe during the Middle Ages. The first historical records of their use in England date to the 11th or 12th centuries and there are reports of German crusaders taking their windmillmaking skills to Syria around 1190. By the 14th century, Dutch windmills were in use to drain areas of the Rhine delta.

Coal Power Internationally, coal is currently the most widely used primary fuel, accounting for approximately 36% of the world''s electricity production. ... Producing electricity from coal starts when the coal is pulverised in huge mills into a fine powder before it is blown into huge kettles, called boilers. Due to the heat in the boiler, the ...

Cohoes Falls Power Plant. ... The 1831 dam also powered Harmony Mills which became the largest cotton mill in the US at the time. By the 1890s AC hydropower was developing rapidly across the nation. In 1915 hydroelectric power was developed next to Harmony Mills. Three 10,000 horsepower generators were built in the original installation.

Other options for power generation can use the land owned by the cement plant for raw material reserves. These include wind farms photovoltaics, concentrated solar panels or growing and burning biomass either to boost power in a WHR system or for use in an internal, standalone power generation plant.

own for analysing its other mills. Industrial Power Plants A power plant producing energy for a pulp and paper mill must operate efficiently "In the processing industry, a power plant operates on the terms of production. As production increases, the power plant produces more heat and electricity – as production decreases, vice versa.

But not all power plant sites were considered suitable. Limiting factors included the lack of available land, low coal costs, and the remaining lifetime of some plants. Factors working in the technology''s favour included reduced coal consumption and plant emissions, and extended working life of power assets and coal resources.

Oct 04, 2009· Steam Turbine use in a Power Plant. A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884.

use of ball mill in thermal power plantxinhai global. Application of Air swept Coal Mill used in thermal power plant, metallurgy, chemical and sugar industry Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory ...

Hydroelectricity is the application of hydropower to generate electricity. It is the primary use of hydropower today. Hydroelectric power plants can include a reservoir (generally created by a dam) to exploit the energy of falling water, or can use the kinetic energy of .

Coal Mills in thermal power plant Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. for thermal powerplant familiarization

usage of mills in power plant. coal power plants mill power consumption Coal Mill in Power Plantcoal mill in power plant Mill Plant Introduction: The mill plant is widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials processing. Get a .

STEEL PLANT PERFORMANCE, POWER SUPPLY SYSTEM DESIGN AND POWER QUALITY ASPECTS ... the plant reactive power consumption within Fig. 2. acceptable limits is the Static Var Compensator (SVC). The typical SVC comprises a set of Fixed ... the reactive power consumption in the rolling mills and the auxiliary systems. Therefore, a

Beater wheel mills are designed to prepare a coal powder airfuel mixture for combustion in furnace chambers of coalfreed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose function usually results in operation instability accompanied by unacceptable vibration.

Whether you''re at a steam power plant, gas power plant or hydroelectric power plant, we can tailor a lubrication reliability program to address your individual maintenance concerns. We can help you protect your steam turbines, gas turbines, generators, boiler feed pumps, ball mills, rod mills and bowl mills with our selection of turbine oils ...

WhatsApp)

WhatsApp)