(PDF) Analysis of material flow and consumption in cement ...

The results show that approximately,, and of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

WhatsApp)

WhatsApp)

The results show that approximately,, and of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

Process Discretion: Wet process, Semidry process, Dry process and Finish process. The environmental im pact of the cement production and its variations between different cement .

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process charac

Aug 30, 2012· Cement Manufacturing Process Phase III: Preheating Raw Material After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln.

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture. .

Aug 21, 2017· Grinding right up the wall or posts is probably the worst part about the grinding process in my opinion. You basically have 2 options. You can use a hand grinder and be on your hands and knees for hours or use a smaller walk behind grinder that has edging capabilities.

costs for cement, it is very important to optimise the existing grinding installations. Experience has shown that the potential for optimisation is greatest in the cement grinding process in a cement plant The benefits that can be achieved due to the optimisation of cement grinding system through process diagnostic study are:

Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delie task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process charac

Cement Grinding Process Pdf. Whatever your requirements, you ''ll find the perfect serviceoriented solution to match your specific needs with our are here for your questions anytime 24/7, welcome your consultation.

Manufacturing Process The cement manufacturing process consist of the following multi stages as explain in the following flow chart. Flow Diagram of Cement Manufacturing Process Wet Processes Dry Processes Raw material preparation (Proportioning and Grinding)

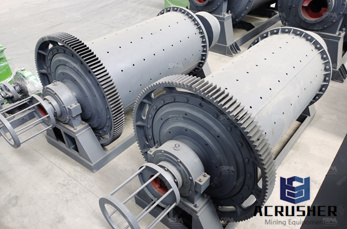

The segmentation of grinding and milling systems. Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and ...

the Cement Grinding Application, based on multivariable model predictive control (MPC) technology, has the flexibility to meet process and quality control requirements. In all cases, design of the control scheme is based on the specific process layout. The process model utilized for process optimization and enhancement

Keywords: Cement industry, computer control, adaptive control, stochastic control, process identification Contents 1. Introduction 2. Description of the Technology Quarrying and Preparation Raw Material Blending Clinker Kilning Cement Grinding 3. Control Problems and Systems Quarrying and Preparations Raw Material ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

After mining, grinding and homogenisation of raw materials; the first step in cement manufacture is calcination of calcium carbonate followed by burning the resulting calcium oxide together with silica, alumina, and ferrous oxide at high temperatures to form clinker.

ty of the cement grinding plant. With the construction of the new grinding plant, the following objectives were aimed at beyond the increase of the grinding capacity:• reduction of the electrical energy •requirement by %, •increased reliability, •high cement qualities, further cement types with finenesses of 3500 to 5000 cm2/g.

Now you''re ready for initial rough grinding of the concrete surface, which will prepare it for final smoothing. This is generally a three to fourstep process, depending on the condition of the concrete. In most cases, you''ll start with a coarse 40grit diamond segment bonded in a metallic

from floor to floor) If the aggregate is deep it will not be worth grinding that deep. Running the grinder at a low RPM may increase grinding speed in the course steps (14 and 30 Grit) by allowing the diamonds to penetrate the floor without overheating. This is most effective on soft concrete or concrete less than a year old. Experiment with speed

Cement Grinding Unit Process In Tamil Huyefilebe. Cement grinding unit process in tamil palashresidencyin. cement mill pdf cement mill process pdf in tamil language dry ultra fine Grinding is the required powdering or pulveriing process when final sie of unit of . Chat; cement manufacturing process tamil pdf wikipedia. Live Chat

The whole process of cement manufacturing in Messebo Cement plant which consists of ... Cement grinding and storage 8. Cement packing and Dispatch . Figure 1: Process and Quality Flow Diagram. 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located km away from

recovered for use in the production process. Cement manufacturing 9. Storage: The clinker store is the source of supply for the cement grinding process. 10. Grinding: Additives are fed in during the clinker grinding process to achieve the required type and grade of cement. 11. Storage, packing and loading: The fi nished cement is

Dry process The raw materials are crushed and fed in the correct proportions into a grinding mill, where they are dried and reduced in size to a fine powder. The dry powder, called raw meal, is then pumped to a blending silo, and final adjustment is now made in the proportions of the materials required for the manufacture of cement.

WhatsApp)

WhatsApp)