Coal Mill of power plant. YouTube

Jun 21, 2018· This is the coal mill of thermal power this is section coal is feed by is mainly ball type mill,coal is pulverized by the ball like powder(70%of 200 mesh) which is used in ...

WhatsApp)

WhatsApp)

Jun 21, 2018· This is the coal mill of thermal power this is section coal is feed by is mainly ball type mill,coal is pulverized by the ball like powder(70%of 200 mesh) which is used in ...

Dec 30, 2017· Power plant takes 5 stone and 5 wood in addition to the power requirements and gold cost. Mill is way cheaper. Only time I make power plants is when I need lots of power really fast, or have no room to build mills.

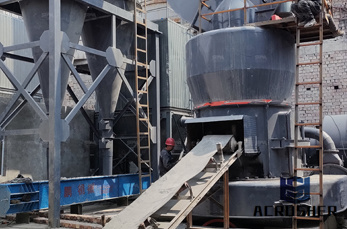

types of roller mill for power plant,types of roller mill for thermal power plant Pulverizer Wikipedia A pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants

From the commercial coal, mainly has washed coal, coal washing, coal powder, coal power plant using coal grinding mill is necessary for into the furnace before, first of all we say about why the thermal power plant coal grinding thermal power plant to coal mill of fine coal particles of coal into irregular, its average particle.

Coal Mills in thermal power plant Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. for thermal powerplant familiarization

Sep 11, 2013· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special ...

Muskogee Mill Power Plant 4901 Chandler Rd Muskogee OK 74403. Reviews. Menu Reservations Make Reservations . Order Online Tickets Tickets See Availability Directions {{::}} Sponsored Topics. Legal. Help Get directions, reviews and information for Muskogee Mill Power Plant in Muskogee, OK. ...

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensing.

Vertical spindle roller mill. Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. ... wheel mills are designed to prepare a coal powder airfuel mixture for combustion in furnace chambers of coalfreed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose ...

locations in coalfired power plants where bearings are typically used, such as in beater wheel mills, tube and bowl mills, and air preheaters. PRODUCTS Everything from one source: From Xlife to service Economical systems in thermal power plants require reliable components. Schaeffler

Jun 09, 2013· MILLS IN A THERMAL POWER STATION PART I Since last 91 post i have discussed various aspect of thermal power plant .Mainly i have written my experience on civil, mechanical, boiler etc. ... 3 stands for Number of grinding Roller. STANDARD MILL CAPACITY MILL SIZE CAPACITY( COAL GRINDING) XRP 623 18 + TPH ...

Coastal power stations, due to their proximity to major urban areas, tend to be better managed in terms of production consistency and environmental standards. In China and India in particular, coastal power stations tend to mill coal more finely, use superior emissions to control technologies, and have a tendency to use higherquality coal blends.

It can be used as desulphurizing absorbent for flue gas desulphurization in power plant. ... It can produce ultrafine powder, low energy consumption low investment cost, large scale ring roller mill has good market prospect. Disadvantage: low output. mill +classifying:

Mar 25, 2017· In this episode we venture into a massive abandoned coal power plant. Check out ThruNite flashlights! ... Steel Mill Blast Furnace Duration: ... Huge Abandoned Coal Mine with Cart Roller Coaster ...

Coal Processing, 088 Lubrication Engineers International. COAL PROCESSING WITH BOWL MILLS (ROLLER OR MULLER). AND BALL, ROD OR ... other industrial and institutional power plants, may vary from location to location. .... 608/605/607 ALMASOL® VariPurpose Gear Lubricant.

Jul 08, 2016· The Eagle Roller Mill and the New Ulm Roller Mill combined to make New Ulm the second largest milling center in Minnesota, trailing only Minneapolis. The mill was closed in 1952, shortly after it was acquired by a Minneapolis competitor. The power plant is the only remaining building from the Eagle mill.

Reliable coal pulverizer performance is essential for sustained fullload operation of today''s power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW''s pulverizers, found at power stations throughout the world.

For nearly 100 years—ever since pulverized coal combustion was adapted for power generation—GE has been a leader in coal mill technology for the power industry. That leadership continues today with the world''s largest fleet of installed power milling equipment.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

It was John Anderson, chief engineer of power plants at the Wisconsin Electric Power Company who introduced pulverized coal firing in power stations. ... roller mills fall in this category, and the third type is the high speed impact mill. The slow speed and medium speed mills are selected for coals ranging from subbituminous to anthracite ...

Fossil fuel power plant Thermal power plant Roller Coal Mills References Bibliography Schumacher Glenn 201 Coal Pulverising Mill Types ISBN 978 Thermal power station Wikipedia the free encyclopedia A thermal power station is a power plant in which heat energy is converted to electric power In most of the world the prime mover is .

Mar 02, 2017· Its design is maintenancefriendly to ensure that you have the maximum plant availability. At its heart, LOESCHE''s wellproven, stateofthe art LM CS vertical roller mill.

29 Jan 2010 ... Thermal power plants use different types of coal pulverizers. The method used ... The key input to the coal fired power plant is the coal. Coal in the form ... MPS mill use tire type rollers and are called "roller mills." The "ball and... GET MORE INFORMATION

WhatsApp)

WhatsApp)