attrition mills,ball mill grinder, YouTube

Jul 08, 2015· Hammer mill working animation HD Duration: ... Foundry Sand Reclamation Shakeout Deck and Attrition Mill Based Systems from Palmer ... GlobeCore Colloid Mill working principle ...

WhatsApp)

WhatsApp)

Jul 08, 2015· Hammer mill working animation HD Duration: ... Foundry Sand Reclamation Shakeout Deck and Attrition Mill Based Systems from Palmer ... GlobeCore Colloid Mill working principle ...

Iz is, in general, different for each size fraction present and is dependent on operating parameters, mill design, the material being milled, and the environment inside the mill. Attrition mill The attrition mill shown with auxiliary equipment (Fig. 1) is basically a device for the intense agitation of a slurry consisting of a coarse rounded ...

MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions. Used for the manufacture of ceramics, inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals. The Attritor is often referred to as a agitated ball mill.

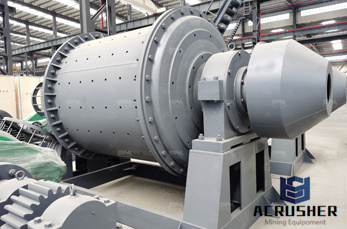

Oct 22, 2013· Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel the barrel rotates, Steel balls or other grinding media in the barrel are lifted t...

working principle of attrition mill animation. Attrition Mills Planetary Ball Mill . Ball mills uses combined impact and attrition methods. In this experiment, we are required to break the coarse salt down using a ball mill and then by using a sieve, the particle size distribution is known. roll, and is removed by a scraper.

The ATTRIMILL is an attrition mill (or kinetic mill) principally used for plastics or fibrous products. It combines three physical principles that generate efficient ultrafine grinding. The autocomminution of the particles generated by the upward air spiral,

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as .

Rod Mill Working Principle Components Mineral Processing ... Jul 28, 2015 ... A Rod Mill has for Working Principle its inside filled grinding media, ... there has been three basic ways of grinding ore, hammer mills, rolls,...

Oversize particles, not easily broken, drop through the mill and may be recycled or discarded. Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage. Fig. 1 Hammer Mill. Attrition Mills. Attrition mills use the hammermill principle to a certain extent;, shattering by ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

Working Principle Of Pebble Mill Working Principle Of Attrition Mill Animation. Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed. » More; attrition mill principle

Working Principle of Crushers On left is a showing of the "standard gyratory with straight concaves " is a section through any vertical, radial plane in the crushing chamber of .

Attrition mill and animation MILL HAMMER WEAR 0 Hammer Mill Working Animation Mineral Processing 4 Mar 2013 Description: Hammer mill The hammers are made from manganese steel or,al mill in power plant YouTube22 Jul 2012, an attrition mill that is plant,Chile Diagram of a Power Plant Pollutions POWER PLANT APPLICATIONS coalfired power plant Coal Mill .

Operating principle of the Attrition mills. The machine works along the same lines as the agitator mills. The vertical special agitator with self rotating hardened dot welded beaters is fitted with agitator shaft which are arranged in staggered positions one above the other and at .

Oct 02, 2018· Hello friend I''m chadra Prakash Pathak from Lucknow. This video is make on the topic of Ball Mill from pharmaceutics1 watching this video and Gain much knowledge about the Ball Mill because its ...

Oct 21, 2009· Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy. A milling machine may also be used for drilling, slotting, making a circular profile and gear cutting by having suitable attachments. Working Principle: The workpiece is holding on the worktable of the machine. The table movement controls the feed ...

Disc attrition machine and its principle of operation Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Disc attrition machine and its principle of operation, quarry, aggregate, and different kinds of minerals.

Similar to the vertical roller mill, it also uses tires to crush coal. There are two types, a deep bowl mill, and a shallow bowl mill. High speed Attrition mill. The attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of .

Jun 22, 2015· Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill).

Nov 30, 2015· DEFINITON: • A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering etc. 6. PRINCIPLE: A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell.

Pin mill work by similar principle as hammer mills (impacts and shearing) but with typically faster tip speed rotorstator configuration of intermeshing pins which impact the particles as solids are directed through the intermesh pins. The mill product leaves by centrifugal forces to the periphery and is then collected or further processed.

ANDRITZ disc mills, also known as attrition mills, are extremely versatile machines. Collectively, our processing technology, experience and knowledge spans more than 100 years, enabling us to custom design and manufacture mills to meet your specific needs.

Rod Mill Working Principle Components. A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS. These rods run the length of the machine, which is most commonly between eight and sixteen feet in length. The diameter of these rods will range from, when new, between two and four inches.

WhatsApp)

WhatsApp)